What is GRP?

GRP stands for Glass Reinforced Polymer/Plastic. It is a composite material (meaning it is formed from at least two different materials) that commonly contains a reinforcing fibre such as fibreglass and a thermoset resin.

Different additives can then be added to change the characteristics of the final product, including colour pigments, UV stabilisers and mineral compounds for fire retardancy. GRP is commonly produced through a moulding method, but can also be made through a pultrusion method, which typically results in a higher load capacity and longer spans.

The result is a unique and versatile product that is perfectly suited to a wide range of applications due to the advantages it brings over more traditional materials.

The Advantages of GRP:

Lightweight yet strong:

The first advantage is that GRP is an extremely lightweight material, particularly compared to more traditional materials such as steel (up to 60% lighter) and concrete (up to 90% lighter). However, it is also very strong, has excellent dimensional stability and is able to withstand a high loading capacity

Easy installation and maintenance:

Due to its lightweight characteristics, GRP is easy to install, particularly useful for remote locations and difficult to reach sites. This saves both time and costs associated with needing heavy lifting equipment and personnel. The products durability and its ability to withstand extreme weather conditions also means it may not require maintenance for up to 20 years. This is a huge benefit for industries such as construction and rail, where maintenance can cause a large amount of disruption. Additionally, using GRP means there is no hot metal working on site.

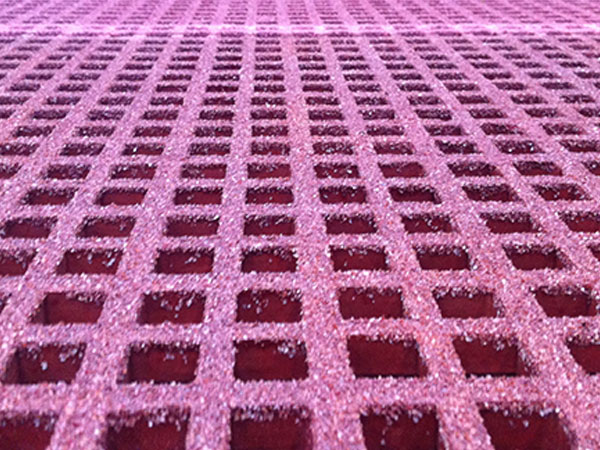

Anti-slip

GRP can be manufactured with a variety of different finishes, including a hard-gritted anti-slip surface, which provides grip and stability even in the most extreme conditions. This makes GRP grating a recommended choice in busy pedestrian areas. It is also ideal for any surfaces that may become slippery in wet conditions, such as marine, factory, or outdoor environments. Anti-slip GRP and solid top in particular provide higher results on PTV testing compared to substitute materials.

Resistance:

GRP is corrosion and weather resistant. This makes it a popular choice over traditional materials which age quickly in harsh environments. The composition of the product can be easily adapted by changing the resin type to improve chemical and fire resistance. Phenolic options are therefore available for use when fire, high temperature, low smoke and toxicity levels are critical parameters. Additionally, the material is non-conductive.

Due to its corrosion resistance, GRP is heavily favoured for use in coastal environments. GRP is highly resistant to water and salt, is not susceptible to mould or rust, and will not deteriorate in extreme weather.

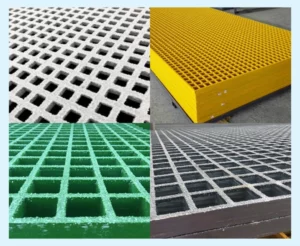

Appearance:

GRP is available in a range of sizes, colours and finishes. This gives great design flexibility as it can easily suit a range of specifications, as well as blending in with existing designs. Bright colours such as yellow can be used to highlight safety routes, or a GRP wood effect could be used to replicate a wooden bridge. This gives great aesthetic versatility.

Cost Effective:

GRP is a competitive solution, like for like with other materials. However, it really comes into its own when taking into account the material’s long lifespan and little to no maintenance benefit. Additionally, GRP has no resale value, reducing the risk of theft.

RF transparent material:

GRP is transparent to radio waves, microwaves and other electromagnetic frequencies. This, paired with its non-conductivity, makes GRP a popular choice in the telecommunications market

The advantages of GRP are very clear, and with a vast product knowledge combined with a wide range of GRP products available, Elemy are sure we can support you with your next project. If you have any further queries, please don’t hesitate to contact us.